DESIGN OF R.C. BEAM - ACI 318-25

1.0 INPUT DATA

Material Properties (ACI 318-25)

fc' = MPa Specified compressive strength of concrete [ACI

19.2.2]

fy = MPa Specified yield strength of reinforcement [ACI

20.2.2]

γc = kN/m³ Unit weight of concrete

Es = MPa Modulus of elasticity of steel

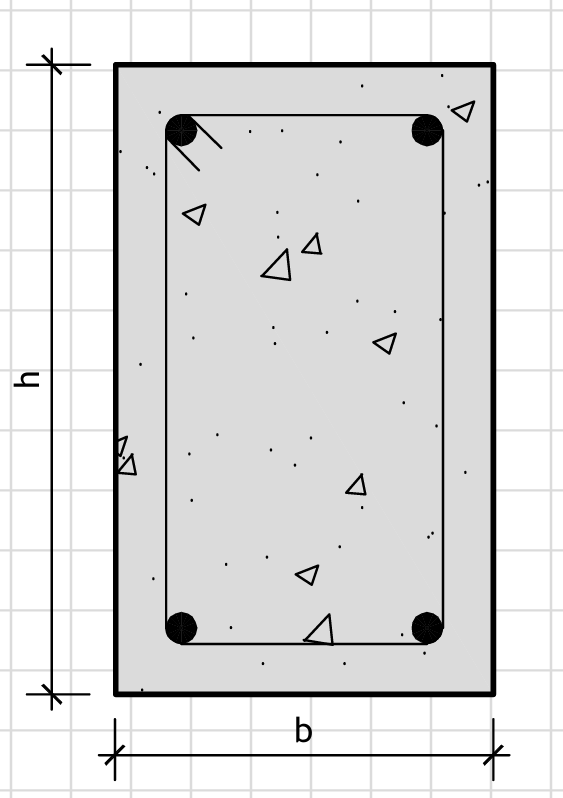

Figure 1: Geometry

RC Beam Dimensions

Load Factors and Strength Reduction Factors

φtension = Strength reduction factor for tension-controlled

sections [ACI 21.2.2]

φshear = Strength reduction factor for shear [ACI 21.2.3]

λ = Modification factor for concrete density [ACI 19.2.4]

Section Dimensions

l =

mm Clear span of beam [ACI 8.7]

h =

mm Overall depth of beam

b =

mm Width of beam

Loads

wD = kN/m Service dead load

wL = kN/m Service live load

M =

kN·m Factored moment at midspan

Vu = kN Factored shear at support

Ma = kN·m Service moment for deflection check

Assumed Reinforcement

cc = mm Clear cover to reinforcement [ACI 20.6]

φmain = mm Main bar diameter

nmain = Number of main bars

φcomp = mm Compression bar diameter (if needed)

ncomp = Number of compression bars (if needed)

φstirrup = mm Stirrup bar diameter

s =

mm Stirrup spacing

cagg,max = mm Maximum aggregate size [ACI 26.4.2.1]

2.0 CALCULATIONS

2.1 Design for Flexure

Effective depth to tension steel

d = h − cc −

φstirrup − φmain/2

d = 450 - 40 - 10 - 20/2 = 380.00 mm

Effective depth to compression steel

d' = cc +

φcomp/2

d' = 40 + 16/2 = 48.00 mm

Provided tension reinforcement

As,prov =

nmain·(φmain/2)²·π

As,prov = 3×(20/2)²×π = 942.48 mm²

ρ = As,prov/(b·d)

ρ = 942.48/(250×380) = 0.0099

Check minimum reinforcement requirement [ACI 9.6.1.2]

ρmin = max(3·√(fc')/fy,

200/fy) Units in psi

ρmin = max(3×√(4352)/60924, 200/60924)

= 0.0018

check_ρmin = OK

(ρ = 0.0099 ≥ ρmin

= 0.0018)

Check maximum reinforcement limit [ACI 9.6.2.1]

β1 = 0.85 (for f'c ≤ 30 MPa)

For normal-weight concrete [ACI 22.2.2.4.3]

ρb =

0.85·β1·fc'/fy ·

Es/(Es + fy) Balanced

reinforcement ratio

ρb = 0.85×0.85×30/420 ×

200000/(200000+420) = 0.0025

ρmax = 0.85·ρb Maximum

reinforcement for tension-controlled sections

ρmax = 0.85×0.0025 = 0.0021

check_ρmax = FAIL

(ρ = 0.0099 ≤ ρmax

= 0.0021)

Check if compression steel is required

Compression steel IS required (ρ > ρmax)

Calculate compression steel requirement

ρcomp = ρ − ρmax

ρcomp = 0.0099 - 0.0021 = 0.0078

As',req =

ρcomp·b·d

As',req = 0.0078×250×380 =

740.63 mm²

Provide compression bars (e.g. 2No.#16)

As',prov =

ncomp·(φcomp/2)²·π

As',prov = 2×(16/2)²×π =

402.12 mm²

check_As' = FAIL

(As',prov = 402.12

< As',req = 740.63 mm²)

Calculate nominal moment strength with compression steel

a =

As,prov·fy/(0.85·fc'·b)

a = 942.48×420/(0.85×30×250) = 62.42 mm

Mn =

As,prov·fy·(d − a/2)

Mn = 942.48×420×(380 - 62.42/2) = 136082976 N·mm

Calculate design moment strength

φMn = φtension·Mn

φMn = 0.9×136082976 = 122474.68 kN·mm = 122.47 kN·m

Check flexural strength

check_flexure = OK

(φMn = 122.47 ≥

M

= 112.50 kN·m)

2.2 Design for Shear - ENHANCED ACI 318-25 PROVISIONS

Shear demand

vu = Vu/(b·d)

vu = 75000/(250×380) = 0.789 MPa

Concrete shear strength [ACI 318-25 Section 22.5.5.1]

vc = 0.17·λ·λs·√(fc')·√(1 +

βc) For beam, βc = 0

λs = √(2/(1 + 0.004·d)) Size effect

factor [ACI 22.5.5.1.3]

λs = √(2/(1 + 0.004×380)) = 0.97

vc =

0.17×λ×λs×√(fc')

vc = 0.17×1.0×0.97×√(30) = 0.90 MPa

vc,min = λ·√(fc')

Minimum concrete shear stress [ACI 22.5.5.2]

vc,min = 1.0×√(30) = 5.477 MPa

vc,design = max(vc,

vc,min)

vc,design = max(0.90, 5.477) =

5.477 MPa

Design concrete shear strength

φv·vc,design =

φshear·vc,design

φv·vc,design = 0.75×5.477 = 4.108

MPa

Design for shear reinforcement

check_shear = OK

(vu = 0.789 ≤

φv·vc,design = 4.108 MPa)

Shear reinforcement design

Vsv,req = Vu −

φv·vc,design·b·d

Vsv,req = 75 -

0.75×5.477×250×380/1000 = 121.1

kN

Asv,req =

Vsv,req·1000/(φshear·fy·d)

Asv,req = 121100/(0.75×420×380) =

1.01 mm²/mm = 1010 mm²/m

Provide stirrups (e.g. #10@150mm c/c)

Asv,prov =

2·(φstirrup/2)²·π/s

Asv,prov = 2×(10/2)²×π/150 =

2.09 mm²/mm = 2090 mm²/m

check_Asv = OK

(Asv,prov = 2090 ≥

Asv,req = 1010 mm²/m)

2.3 Serviceability - Deflection Check

Effective moment of inertia [ACI 24.2.3.5]

Ie =

min[(Mcr/Ma)³·Ig + [1 −

(Mcr/Ma)³]·Icr,

Ig]

Mcr =

fr·Ig/(yt)

fr = 0.62·λ·√(fc') Modulus of

rupture

fr = 0.62×1.0×√(30) = 3.40 MPa

Ig = b·h³/12

Ig = 250×450³/12 = 3785156250 mm⁴

yt = h/2 Distance from centroid to

extreme tension fiber

yt = 450/2 = 225 mm

Mcr = 3.40×3785156250/225 = 57156406 N·mm = 57.16 kN·m

Icr = n·As·(d −

c)² + b·c³/3

c = √[(n·As)² +

2·n·As·d] − n·As

Ec =

4700·√(fc')·√(γc/23.5)

Ec = 4700×√(30)×√(24/23.5) = 25740 MPa

n = Es/Ec

n = 200000/25740 = 7.77

c = √[(7.77×942.48)² + 2×7.77×942.48×380] − 7.77×942.48

= 39.16 mm

Icr = 7.77×942.48×(380-39.16)² +

250×39.16³/3 = 87709076 mm⁴

Service moment (user-provided for deflection check)

Ma = 78.13 (user input) kN·m

Ie = min((57.16/78.13)³×3785156250 +

[1−(57.16/78.13)³]×87709076, 3785156250) = 87709076 mm⁴

Deflection calculation (simple span, uniformly distributed load)

Δ = 5·(wD +

wL)·l⁴/(384·Ec·Ie)

Δ = 5×25×6000⁴/(384×25740×87709076) = 8.43 mm

Check deflection limits [ACI Table 24.2.2]

Allowable Δ = l/240 = 6000/240 = 25.00 mm

check_deflection = OK

(Δ = 8.43 ≤ Allowable = 25.00 mm)

2.4 Crack Control [ACI 24.3]

Calculate z-factor for beam

z =

β·hc·√(dc·A) [ACI

24.3.2]

β = d/(dc) = 380/(40+10+20/2) = 4.75

hc = cc + φstirrup +

φmain/2

hc = 40 + 10 + 20/2 = 60 mm

dc = hc

A = 2·dc·(b/nmain)

A = 2×60×(250/3) = 10000 mm²

z = 4.75×60×√(60×10000) = 36898 N/mm

check_crack = FAIL

(z = 36898 > 30000 N/mm for interior exposure)

2.5 Bar Spacing Requirements [ACI 25.2]

Minimum spacing requirements [ACI 25.2.1]

smin = max(φmain,

1.33·cagg,max, 25 mm)

smin = max(20, 1.33×19, 25) = 25.00 mm

check_smin = OK

(Spacing between bars ≥ 25.00 mm)

Maximum spacing for crack control [ACI 24.3.2]

smax,crack = min(12×dc,

300) mm For interior exposure with moderate corrosion risk

smax,crack = 300.00

mm

check_smax,crack = OK

(Provide adequate spacing for crack control)

Stirrup spacing check [ACI 9.7.6.2]

smax,stirrup = min(16×φmain,

d/2, 300) mm

smax,stirrup = 190.00

mm

check_sstirrup = OK

(s = 150 ≤

smax,stirrup

= 190.00 mm)

*** OUTPUT SUMMARY ***

Design Results

Effective depth, d = 380.00

mm

Provided tension steel, As,prov = 942.48 mm²

Required compression steel, As',req = 740.63 mm²

Provided compression steel, As',prov = 402.12 mm²

Reinforcement ratio, ρ = 0.0099

Design moment strength, φMn = 122.47 kN·m

Flexural strength check: OK

Compression steel check: FAIL - Increase compression steel

Shear stress, vu = 0.789 MPa

Design concrete shear strength, φv·vc,design =

4.108 MPa

Shear capacity check: CHECK

Calculated deflection, Δ = 8.43

mm

Allowable deflection = 25.00

mm

Deflection check: OK

Crack control check: FAIL - Increase cover or reduce spacing

Bar spacing check: OK

RESULTS

DESIGN FAILS - INCREASE COMPRESSION STEEL AND IMPROVE CRACK CONTROL