Method = Select design methodology

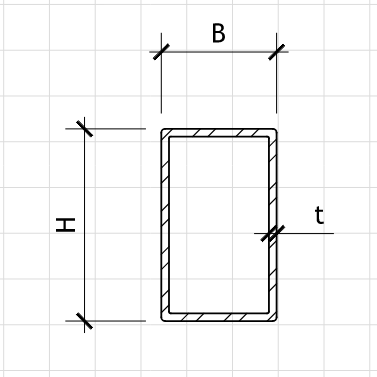

Member Geometry (RHS-Section)

L = ft Member Length

b = in Section Width (Outer)

h = in Section Height (Outer)

t = in Wall Thickness

Figure 1: Geometry

RHS-Section Dimensions

Material Properties (ASTM A500 Grade C)

E = ksi Elastic Modulus

Fy = ksi Yield Strength

Fu = ksi Ultimate Tensile Strength

Axial Loads (Tension Positive, Compression Negative)

ND = kips Dead Load Axial Force

NL = kips Live Load Axial Force

Bending Loads

wD = klf Dead Load (Uniformly Distributed)

wL = klf Live Load (Uniformly Distributed)

PD = kips Dead Load (Point Load at Midspan)

PL = kips Live Load (Point Load at Midspan)

End Restraints

Kx = Effective Length Factor (x-axis)

Ky = Effective Length Factor (y-axis)

Kz = Effective Length Factor (torsional)

LRFD Load Factors:

wu = 1.2·wD + 1.6·wL = 2.60 klf Factored Distributed Load

Pu = 1.2·PD + 1.6·PL = 44.00 kips Factored Point Load

Nu = 1.2·ND + 1.6·NL = 0.00 kips Factored Axial Force

ASD Load Factors:

wa = wD + wL = 1.50 klf Allowable Distributed Load

Pa = PD + PL = 30.00 kips Allowable Point Load

Na = ND + NL = 0.00 kips Allowable Axial Force

Mmax = w·L²/8 + P·L/4 = 136.25 kip-ft Maximum Design Moment

Vmax = w·L/2 + P/2 = 30.50 kips Maximum Design Shear

bi = b − 2·t = 7 in Inner Width

hi = h − 2·t = 11 in Inner Height

Ag = b·h − bi·hi = 12.25 in² Gross Area

Ix = 269.4 in⁴ Second Moment of Area (strong axis)

Iy = 131.5 in⁴ Second Moment of Area (weak axis)

Sx = 44.9 in³ Elastic Section Modulus (x-axis)

Sy = 32.9 in³ Elastic Section Modulus (y-axis)

Zx = 57.3 in³ Plastic Section Modulus (x-axis)

rx = 4.69 in Radius of gyration (x-axis)

ry = 3.28 in Radius of gyration (y-axis)

J = 455.1 in⁴ Torsional Constant

Tension Strength (Chapter D)

Ag = 12.25 in²

Pn = Fy·Ag = 612.5 kips Nominal Tension Capacity

φt = 0.90 Resistance Factor (LRFD)

φtPn = 551.3 kips Design Tension Strength (LRFD)

Pn/Ωt = 366.8 kips Allowable Tension Strength (ASD)

Tension Check: Tensionratio = |N|·φtPn−1 = 0.000

Compression Strength (Chapter E)

Lc,x = Kx·L·12 = 240 in Effective Length (x-axis)

Lc,y = Ky·L·12 = 240 in Effective Length (y-axis)

Lc,z = Kz·L·12 = 240 in Effective Length (torsional)

rmin = min(rx, ry) = 3.28 in Minimum Radius of Gyration

λ = Lc/rmin = 73.2 Slenderness Parameter

Fe = π²·E/λ² = 5.35 ksi Euler Buckling Stress

Fcr = 0.877·Fe = 4.69 ksi Critical Buckling Stress

Pn = Fcr·Ag = 57.5 kips Nominal Compression Capacity

φcPn = 51.8 kips Design Compression Strength (LRFD)

Pn/Ωc = 34.4 kips Allowable Compression Strength (ASD)

Compression Check: Compressionratio = |N|·φcPn−1 = 0.000

Bending Strength (Chapter F)

Mn,x = Fy·Zx = 238.8 kip-ft Nominal Moment Capacity (x-axis)

φb = 0.90 Resistance Factor (LRFD)

φbMn,x = 179.1 kip-ft Design Moment Strength (LRFD)

Bending Check: Bendingratio = Mmax/(φbMn,x) = 0.761

Combined Axial and Bending (Chapter H)

Pu/(φcPn) = 0.000

Mu/(φbMn) = 0.761

Interaction Check: Interactionratio = Pu/(φcPn) + Mu/(φbMn) = 0.761

Shear Strength (Chapter G)

Av,x = 2·(h−2·t)·t = 11.00 in² Shear Area (x-axis)

Vn,x = 0.6·Fy·Av,x = 330.0 kips Nominal Shear Strength (x-axis)

φvVn,x = 297.0 kips Design Shear Strength (LRFD)

Shear Check: Shearratio = Vmax/(φvVn,x) = 0.103

Deflection Check (Serviceability)

δmax = 5·wL·L⁴/(384·E·Ix) + PL·L³/(48·E·Ix) = 0.78 in

δlimit = L/360 = 0.67 in

Deflection Check: Deflectionratio = δmax/δlimit = 1.16

Compact Section Check (AISC Section B4)

λp = 0.38·√(E/Fy) = 10.8 Limiting λ for compact flange

λf = (b/t) = 16.00 Flange slenderness

λpw = 2.42·√(E/Fy) = 68.9 Limiting λ for compact web

λw = (h−2·t)/t = 22.00 Web slenderness

Section Classification: Compact