Method = Select design approach per EN 1990

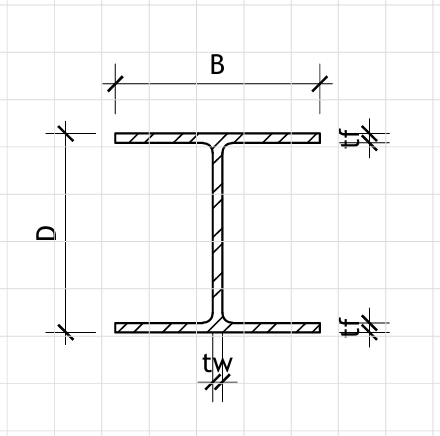

Member Geometry (I-Section)

L = m Member Length

h = mm Section Depth

b = mm Flange Width

tf = mm Flange Thickness

tw = mm Web Thickness

Figure 1: Geometry

I-Section Dimensions

Material Properties (EN 10025-2 S275)

E = MPa Elastic Modulus

fy = MPa Yield Strength

fu = MPa Ultimate Tensile Strength

Actions (kN, kN/m)

Gk = kN/m Permanent Actions (Dead Load)

Qk,1 = kN/m Variable Actions (Live Load)

NG = kN Permanent Axial Force

NQ = kN Variable Axial Force

Partial Factors (EN 1990)

γG = Partial Factor for Permanent Actions

γQ = Partial Factor for Variable Actions

Imperfections

α = Imperfection Factor (EN 1993-1-1 Table 6.1)

K = Effective Length Factor

Ed = 1.35·Gk + 1.50·Qk,1 = 52.75 kN/m Design Value of Distributed Load

NEd = 1.35·NG + 1.50·NQ = 192.50 kN Design Value of Axial Force

MEd = Ed·L²/8 = 237.38 kN·m Design Value of Maximum Moment

VEd = Ed·L/2 = 158.25 kN Design Value of Maximum Shear

hw = h − 2·tf = 276 mm

A = 2·b·tf + hw·tw = 62.88 cm² Cross-sectional Area

Iy = 8333.33 cm⁴ Second Moment of Area (strong axis)

Iz = 320.00 cm⁴ Second Moment of Area (weak axis)

Wel,y = 555.56 cm³ Elastic Section Modulus (strong axis)

Wpl,y = 622.22 cm³ Plastic Section Modulus (strong axis)

iy = 11.51 cm Radius of gyration (strong axis)

iz = 2.26 cm Radius of gyration (weak axis)

Tension Resistance (Clause 6.2.3)

Npl,Rd = A·fy/γM0 = 1729.20 kN Design Plastic Resistance in Tension

Nu,Rd = 0.6·Anet·fu/γM2 = 1621.75 kN Design Resistance for Net Section

Tension Check: NEd/Npl,Rd = 0.111

Compression Resistance (Clause 6.2.4)

λ̄ = L/(i·π)·√(fy/E) = 0.83 Normalized slenderness

χ = 1/(Φ + √(Φ² − λ̄²)) = 0.74 Reduction factor

Φ = 0.5·[1 + α(λ̄ − 0.2) + λ̄²] = 0.93 Initial imperfection factor

Nb,Rd = χ·A·fy/γM1 = 1279.56 kN Design Buckling Resistance

Compression Check: NEd/Nb,Rd = 0.151

Bending Resistance (Clause 6.2.5)

Mc,Rd = Wpl,y·fy/γM0 = 1711.11 kN·m Design Moment Resistance

Bending Check: MEd/Mc,Rd = 0.139

Combined Axial and Bending (Clause 6.2.9)

MN,Rd = Mc,Rd·(1 − NEd/Npl,Rd) = 1519.89 kN·m Reduced Moment Resistance

Interaction Check: NEd/Nb,Rd + MEd/MN,Rd = 0.285

Shear Resistance (Clause 6.2.6)

Av = h·tw = 24.00 cm² Shear Area

Vpl,Rd = Av·fy/(√3·γM0) = 382.92 kN Design Shear Resistance

Shear Check: VEd/Vpl,Rd = 0.413

Deflection Check (Serviceability)

δmax = 5·Gk·L⁴/(384·E·Iy) = 8.52 mm

δlimit = L/250 = 24.00 mm

Deflection Check: δmax/δlimit = 0.355

Section Classification (EN 1993-1-1 Table 5.2)

c/tf = (b − tw)/(2·tf) = 8.00 Flange slenderness ratio

ε = √(235/fy) = 0.92 Material coefficient

Class 1 limit = 9·ε = 8.31 Class 1 flange limit

Class 2 limit = 10·ε = 9.23 Class 2 flange limit

Section Classification: Class 1