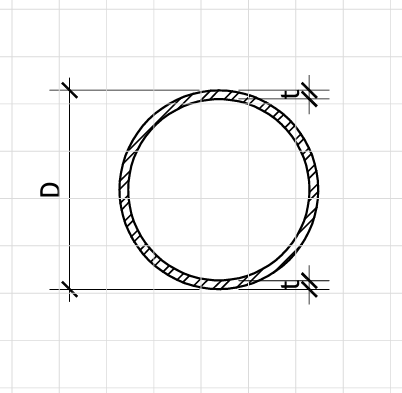

D = mm Outer diameter

t = mm Wall thickness

fy = MPa Yield strength for steel grade S355

E = MPa Modulus of elasticity for steel

Figure 1: Geometry

CHS-Section Dimensions

Ned = kN Axial force - positive for tension, negative for compression

Ved = kN Shear force

Med = kNm Bending moment

L = mm Member length (mm)

Le/L = Effective length factor

Le = 10000 mm Effective length (mm) for compression check

γm0 = For resistance of cross-sections

γm1 = For resistance of members to instability

dinner = D - 2×t = 72 mm

A = π×(D² - dinner²)/4 = 464.96 mm² Gross cross-sectional Area

I = π×(D⁴ - dinner⁴)/64 = 318495 mm⁴ Second Moment of Area

Wel = I/(D/2) = 8381.44 mm³ Elastic section modulus

Wpl = (D³ - dinner³)/6 = 10954.7 mm³ Plastic section modulus

ε = √(235/fy) = 0.814

d/t = 38

Section Class: 2

Axial Resistance

Nc,Rd = A×fy/γm0 = 165.06 kN

Axial ratio = |Ned|/Nc,Rd = 0.005

Capacity: Nres,k = 165.06 kN

Shear Resistance

Av = 2×A/π = 296 mm²

Vpl,Rd = Av×(fy/√3)/γm0 = 60.67 kN

Shear ratio = |Ved|/Vpl,Rd = 0.009

Capacity: Vres,k = 60.67 kN

Bending Resistance

Weff = Wpl = 10954.7 mm³

Mc,Rd = Weff×fy/γm0 = 3.89 kNm

Bending ratio = |Med|/Mc,Rd = 0.339

Capacity: Mres,k = 3.89 kNm

Member Buckling

Ncr = π²×E×I/Le² = 6.60 kN

λ̄ = √(A×fy/Ncr) = 5.00

α = 0.21 Imperfection factor for CHS, curve a

φ = 0.5×(1 + α×(λ̄ - 0.2) + λ̄²) = 13.51

χ = 1/(φ + √(φ² - λ̄²)) = 0.038

Nb,Rd = χ×Nc,Rd = 6.34 kN

Buckling ratio = |Ned|/Nb,Rd = 0.122

Capacity: Nb,res,k = 6.34 kN

Simplified check for combined actions. Full check requires complex Annex A or B factors.

Interaction ratio = |Ned|/min(Nc,Rd, Nb,Rd) + |Med|/Mc,Rd = 0.461

Maximum ratio = 0.461

All checks are within acceptable limits (ratio ≤ 1.0)