DESIGN OF R.C. TWO-WAY SOLID SLAB - HK CoP 2013

1.0 INPUT DATA

Material Properties

fcu = MPa Characteristic concrete cube strength

fy = MPa Characteristic steel yield strength [Clause 3.2.1.1]

fy,comp = N/mm² Characteristic steel yield strength for

compression steel

γc = Partial safety factor for concrete

γs = Partial safety factor for steel

Ratiobasic = Basic span/effective depth ratio [Table 3.9]

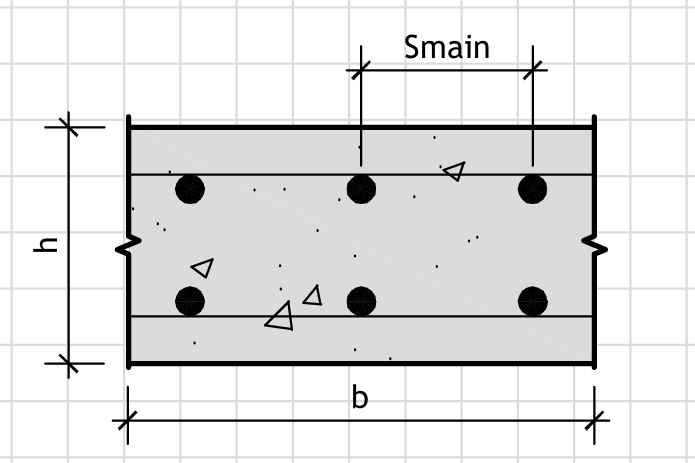

Section Dimensions

lx = mm Length of short span

ly = mm Length of long span

h =

mm Overall depth of slab

b =

mm Slab width for design

Figure 1: Geometry

RC Slab Dimensions

Loading

wult = kPa Design ultimate load (per area)

wservice = kPa Design service load (per area)

Boundary Condition

Select support condition [Table 6.6]:

Assumed Reinforcement Sizes and Cover

cnom = mm Nominal cover

φx = mm Short span main bar diameter

Sx = mm Short span main bar spacing

φy = mm Long span main bar diameter

Sy = mm Long span main bar spacing

φcomp = mm Compression bar diameter (if needed)

2.0 CALCULATIONS

2.1 Ultimate Limit State (ULS) - Bending

Aspect ratio

ly/lx = 7800/5600

= 1.393

Effective depths

dx = h − cnom −

φx/2 (Effective depth to short span steel)

dx = 250 - 35 - 12/2 = 209.00 mm

dy = h − cnom −

φx − φy/2 (Effective depth to long span

steel)

dy = 250 - 35 - 12 - 12/2 = 197.00 mm

dcomp = cnom +

φcomp/2 (Effective depth to compression steel)

dcomp = 35 + 12/2 = 41.00 mm

Step 1: Moment coefficients (βsx,

βsy)

Values from Table 6.6 with linear interpolation for intermediate aspect ratios. You can override

these values if needed.

For ly/lx = 1.393

βsx =

(Short span moment coefficient)

βsy =

(Long span moment coefficient)

Step 2: Calculate design moments

Short span moment

Msx = βsx · wult ·

lx² · 1m

Msx = 0.0313 × 12.6 × 5.6² × 1 = 12.39 kN·m

Long span moment

Msy = βsy · wult ·

lx² · 1m

Msy = 0.0429 × 12.6 × 5.6² × 1 = 16.99 kN·m

Step 3: Design reinforcement for short span (per 1m width)

Kx = Msx/(b ·

dx² · fcu)

Kx = 12.39×10⁶/(1000×209²×45) = 0.0063

Kbal = 0.156 (Maximum K for singly reinforced

section)

Compression steel NOT required in short span (Kx

< Kbal)

K'x = 0.0063

Lever arm for short span

zx = min(dx · (0.5 + √(0.25 −

K'x/0.9)), 0.95 · dx)

zx = min(209×(0.5 + √(0.25 - 0.0063/0.9)),

0.95×209)

zx = 198.55

mm

Tension steel required (short span)

Asx,req =

Msx/(fy/γs ·

zx)

Asx,req = 12.39×10⁶/(500/1.15×198.55)

= 143.51 mm²

Provide bars (e.g. T12@200mm)

Asx,prov = b · (φx/2)² ·

π/Sx

Asx,prov = 1000×(12/2)²×π/200 = 565.49 mm²

Compression steel required (short span)

Asxc,req = 0.00

mm² (Not required)

Check tension reinforcement (short span)

check_Asx = OK

(Asx,prov = 565.49 ≥

Asx,req = 143.51 mm²)

Step 4: Design reinforcement for long span (per 1m width)

Ky = Msy/(b ·

dy² · fcu)

Ky = 16.99×10⁶/(1000×197²×45) = 0.0097

Kbal = 0.156 (Maximum K for singly reinforced

section)

Compression steel NOT required in long span (Ky

< Kbal)

K'y = 0.0097

Lever arm for long span

zy = min(dy · (0.5 + √(0.25 −

K'y/0.9)), 0.95 · dy)

zy = min(197×(0.5 + √(0.25 - 0.0097/0.9)),

0.95×197)

zy = 187.15

mm

Tension steel required (long span)

Asy,req =

Msy/(fy/γs ·

zy)

Asy,req = 16.99×10⁶/(500/1.15×187.15)

= 208.92 mm²

Provide bars (e.g. T12@200mm)

Asy,prov = b · (φy/2)² ·

π/Sy

Asy,prov = 1000×(12/2)²×π/200 = 565.49 mm²

Compression steel required (long span)

Asyc,req = 0.00

mm² (Not required)

Check tension reinforcement (long span)

check_Asy = OK

(Asy,prov = 565.49 ≥

Asy,req = 208.92 mm²)

2.2 Ultimate Limit State (ULS) - One-way Shear Check (short direction)

Maximum shear at support

Shear Factor = (Distribution factor, typically 0.5 for simply

supported)

Vx = wult · lx ·

Shear Factor · 1m

Vx = 12.6 × 5.6 × 0.5 × 1 = 35.28 kN

Applied shear stress

vx = Vx/(b ·

dx)

vx = 35.28×10³/(1000×209) = 0.169 MPa

Permissible shear stress in concrete

vc = 1 MPa · (0.79 · (100 ·

Asx,prov/(b · dx))1/3 · max(0.67,

(400/dx)1/4) · (fcu/25

MPa)1/3)/γc

vc = 1×(0.79×(100×565.49/(1000×209))¹ᐟ³×max(0.67,

(400/209)¹ᐟ⁴)×(45/25)¹ᐟ³)/1.25

vc = 0.475

MPa

Maximum shear stress [Clause 3.4.5.2]

vmax = min(0.8 · √(fcu/1 MPa), 5) × 1

MPa

vmax = min(0.8×√(45/1), 5)×1 = 5.000 MPa

Check shear stress

check_vx,max = OK

(vx = 0.169 ≤

vmax = 5.000 MPa)

check_vx,c = OK

(vx = 0.169 ≤

vc = 0.475 MPa)

Shear reinforcement is not required

2.3 Serviceability Limit State (SLS) - Deflection Check

Short span is critical for deflection

Service moment (short span)

Mservice,x = βsx ·

wservice · lx² · b

Mservice,x = 0.0313 × 12.6 × 5.6² × 1

= 12.39 kN·m

Required service steel (short span)

As,req,service,x =

Mservice,x/(fy/γs ·

zx)

As,req,service,x = 12.39×10⁶/(500/1.15×198.55) = 143.51 mm²

Modification factor for tension reinforcement

Factormod = min(0.55 + (477 MPa − 2 · fy ·

As,req,service,x/(3 · Asx,prov))/(120 · (0.9 MPa +

Mservice,x/(b · dx²))), 2)

Factormod = min(0.55 + (477 -

2×500×143.51/(3×565.49))/(120×(0.9 + 12.39×10⁶/(1000×209²))), 2)

Factormod = 1.632

Allowable span/effective depth ratio

Ratioallow = Ratiobasic ·

Factormod

Ratioallow = 20×1.632 = 32.64

Actual span/effective depth ratio

Ratioactual =

lx/dx

Ratioactual = 5600/209 = 26.79

Check deflection

check_deflection = OK

(Ratioactual = 26.79 ≤

Ratioallow = 32.64)

*** OUTPUT SUMMARY ***

Design Summary

Aspect ratio (ly/lx): 1.393

Short span moment, Msx = 12.39 kN·m

Long span moment, Msy = 16.99 kN·m

Required tension steel (short span), Asx,req = 143.51 mm²

Provided tension steel (short span), Asx,prov = 565.49 mm²

Tension reinforcement check (short span): OK

Required tension steel (long span), Asy,req = 208.92 mm²

Provided tension steel (long span), Asy,prov = 565.49 mm²

Tension reinforcement check (long span): OK

Required compression steel (short span): Asxc,req = 0.00 mm²

Required compression steel (long span): Asyc,req = 0.00 mm²

Design shear stress (short span), vx = 0.169 MPa

Allowable shear stress in concrete, vc = 0.475 MPa

Shear capacity check (short span): OK - Shear reinforcement not required

Actual span/depth ratio (short span), Ratioactual = 26.79

Allowable span/depth ratio, Ratioallow = 32.64

Deflection check: OK

RESULTS

ALL CHECKS PASSED - DESIGN IS ADEQUATE